-

Equipment and Tools

-

Aerial Work Platforms, Scaffolding And Ladders

- See all

- Atrium Lift

- Cranes / Boom Trucks

- Electric Scissorlifts

- Low-Level Access

-

Manlift Articulating

- See all

- Manlift Articulating 120' - 135' Combustion

- Manlift Articulating 30' - 39' Combustion

- Manlift Articulating 30' - 39' Electric

- Manlift Articulating 34' - 39' Towable

- Manlift Articulating 40' - 49' Combustion

- Manlift Articulating 40' - 49' Electric

- Manlift Articulating 50' - 59' Towable

- Manlift Articulating 60' - 69' Combustion

- Manlift Articulating 60' - 69' Electric

- Manlift Articulating 80' - 89' Combustion

- Manlift Straight Boom

- Mast Boom Lift

- One Man Drivable

- One Man Push Arounds

- Power Accessories

- Rt Scissor

- Scaffolding And Ladders

- Straddle Adapter

-

Air Compressors And Air Tools

- See all

- Air Compressor Aftercoolers / Filters / Separators / Dryers

-

Air Compressors

- See all

- Air Compressors 1000cfm - 1300cfm

- Air Compressors 1000cfm - 1300cfm Instrument Quality

- Air Compressors 1500cfm - 1800cfm Instrument Quality

- Air Compressors 300cfm - 400cfm

- Air Compressors 300cfm - 400cfm Instrument Quality

- Air Compressors 5cfm - 85cfm

- Air Compressors 600cfm - 900cfm

- Air Compressors 600cfm - 900cfm Instrument Quality

- Air Compressors 90cfm - 250cfm

- Air Compressors Electric 100cfm - 1000cfm

- Air Compressor Accessories

- Air Impact Wrenches

- Air Nailers & Staplers

- Air Tools - Contractor

- Air Tools - Demolition

- Air Tools - Industrial

- Compaction

-

Concrete And Masonry

- See all

- Battery Powered Saw

- Concrete - Finishing Equipment

- Concrete - Surface Preparation Equipment

-

Concrete / Masonry - Cutting & Drilling Equipment

- See all

- Concrete& Asphalt Floor Saws - Push Type

- Concrete And Masonry Blades

- Concrete Dowel Drills

- Core Drill Bits

- Crack Chasers

- Cutoff Saws Hand Held/ Gas/ Air/ Electric/ Hydraulic

- Diamond Chain Saws

- Diamond Core Drills

- Early Entry Concrete Saws

- Masonry Saws

- Street Saws Self-Propelled

- Tile Saws

- Concrete Water Accessories

- Concrete / Masonry - Mixing & Placing Equipment

-

Cooling, Heating, Drying And Indoor Air Quality

- See all

- Air Management - Accessories

- Air Management - Air Scrubbers

- Air Management - Dehumidifier

- Air Management - Fans & Blowers

- Boilers

- Cooling - Air Conditioning

- Cooling - Air Handlers

- Cooling - Chillers

- Cooling - Cooling Tower

- Cooling - Spot Cooler

- Fans / Blowers / Ventilators

- Heating - Accessories

-

Heating - Direct Fired

- See all

- 201k-300k Btu Kerosene Heater Dir

- 20k-80k Btu Kerosene Heater Dir

- 301k-400k Btu Kerosene Heater Dir

- 301k-400k Btu Lp/Ng Heater Dir

- 40k-70k Btu Kerosene Heater Dir

- 81k-200k Btu Kerosene Heater Dir

- Propane Convection& Radiant Heaters 22k - 200k Bt

- Propane/Natural Gas Direct-Fired Heaters 30k-2.5m

- Heating - Electric

- Heating - Flameless

- Heating - Hydronic / Ground

-

Heating - Indirect Fired

- See all

- 1000k Btu And Up Kerosene Heater

- 1000k Btu And Up Lp/Ng Heater

- 1mil - 5mil Btu Diesel Heater

- 201k-300k Btu Kerosene Heater

- 301k-400k Btu Kerosene Heater

- 301k-400k Btu Lp/Ng Heater

- 401k-500k Btu Kerosene Heater

- 401k-500k Btu Lp/Ng Heater

- 501k-999k Btu Diesel Heater

- 501k-999k Btu Kerosene Heater

- 501k-999k Btu Lp/Ng Heater

- 81k-200k Btu Kerosene Heater

- Heating - Steam / Hot Water

-

Earth Moving

- See all

- Backhoe Loaders

- Dozers & Crawler Loaders

- Excavators

- Hydraulic Breakers & Demolition Attachments

- Mini Excavators

- Motor Graders

- Rental Vehicles

-

Skidsteer Loaders

- See all

- Compact Skidsteer Loader

- Skidsteer Loader 999lb& Under

- Skidsteer Loader 1000-1499lb

- Skidsteer Loader 1100-1500lb Track

- Skidsteer Loader 1500-2000lb

- Skidsteer Loader 1500-2100lb Track

- Skidsteer Loader 2000-2800lb

- Skidsteer Loader 2100-2800lb Track

- Skidsteer Loader 2800-3200lb Track

- Ride On Skidsteer Attachments

- Skidsteer Attachments

- Tractors & Landscape Loaders

- Trenchers

- Wheel Loaders

- Floor Care

-

Forklifts

- See all

- Forklift Accessories

- Forklifts - Industrial

- Forklifts - Straight Mast Rt

- Forklifts - Telehandler

-

Material Handling Equipment

- See all

- Aluminum Dockplates

- Aluminum Loading Ramps

- Appliance Trucks

- Banding Kits

- Cricket Pipe Dolly

- Dry Wall Lift& Carts

- Duct Jacks/ Genie Material Lifts

- Glass Manipulators

- Grasshopper Pipe Dolly

- Hand Trucks

- Hilman Rollers/ Roller Skid Systems

- Hydraulic Rol-A-Lift

- Johnson Bar/ Pry Dollies

- Load Binders

- Pallet Pullers

- Pallet Trucks

- Platform Trucks

- Roust-A-Bout Portable Lift

- Stairclimbing Motorized Hand Trucks

- Warehouse Dolly

-

General Construction Tools

- See all

- Abrasive Blasting Equipment

- Batteries And Chargers

- Battery Powered Air Compressor

-

Battery Powered Tools

- See all

- Angle Grinders - Battery

- Circular Saws - Battery

- Compound Miter Saws - Battery

- Drywall Screwdrivers - Battery

- Hand-Held Band Saw - Battery

- Hand-Held Drills - Battery

- Impact Wrenches - Battery

- Miscellaneous - Battery

- Nailers - Battery

- Orbital Sanders - Battery

- Portable Table Saw - Battery

- Reciprocating Saws - Battery

- Rotary And Demolition Hammers - Battery

- Battery Powered Vacuum

- Chain Hoists & Air Winches

- Conveyors

- Drain & Sewer Cleaning & Inspections

-

Electric Tools

- See all

- Angle Grinders

- Belt Sanders

- Circular Saws

- Compound Miter Saws

- Die Grinders

- Drywall Screwdrivers

- Hand-Held Band Saw

- Hand-Held Drills

- Heat Gun

- Impact Wrenches

- Jigsaws

- Magnetic Drills

- Orbital Sanders

- Planers

- Portable Table Saw

- Reciprocating Saws

- Rotary And Demolition Hammer Accessories

- Rotary And Demolition Hammers

- Routers

- Shears& Nibblers

- Stationary Chop Saw

- Hydraulic / Electric Torque Wrenches / Enerpac

- Hydraulic Cylinders / Enerpac Jacking Systems

- Hydraulic Pumps / Enerpac

- Hydraulic Tools / Enerpac

- Industrial Vehicles

- Jacks - Bottle / Screw / Toe Jack

- Laser & Optical Levels

- Lighting Equipment

-

Mechanical & Electrical Contractor Trade Tools

- See all

- Cable Feeder

- Cable Reel Roller - Electric

- Cable Reel Stands/ Spindles

- Chain Vice/ Tri-Stand/ Pipe Stands

- Crimping Tools - Electric

- Crimping Tools - Manual

- Electric Cable Pullers& Sheaves

- Electric Conduit Benders

- Electric Pvc Heaters/ Pvc Benders

- Geared Threader/ Hog Head

- Hole Cutting Tool

- Hydraulic Conduit Benders

- Hydraulic Punch Drivers/ Knockout Sets

- Manual Pipe Tools& Accessories

- Mechanical Conduit Benders

- Pipe Threaders - Electric

- Power Fish System

- Power Pipe Cutters

- Victaulic Roll Groovers

- Wire Carts/ Dispensers

- Miscellaneous

- Paint Sprayers

- Pressure Washers

- Siding Brake

- Site Services

- Storage Containers / Jobsite Storage

- Traffic Safety Equipment

- Trailers

- Welding & Plasma Cutting Equipment

- Generators And Accessories

- Ground Protection

-

Lawn, Landscape, And Tree

- See all

- Battery Powered Lawn & Landscape

-

Lawn & Landscape

- See all

- Backpack Sprayer

- Bed Edger/ Trencher

- Chain Saws

- Garden Tillers

- Gas-Powered Drill

- Hand Tools

- Hand-Held Metal Detector

- Hedge Trimmers

- Hydroseeder

- Lawn Aerators

- Lawn Dethatchers

- Lawn Mowers& Brush Cutters

- Lawn Overseeder

- Lawn Spreader& Roller

- Lawn Vacuum

- Leaf Blowers/ Mulchers

- Log Splitter

- Post Driver

- Post Hole Augers

- Sod Cutters

- Straw Blowers

- Trimmers& Pruners

- Wheelbarrows

- Stump Grinders

- Wood & Brush Chippers

- Load Banks

- Portable Ice Rinks And Pathways

- Pumps

- Refrigeration

- Temporary Containment Walls

- Temporary Fencing

- Temporary Structures

- Trench And Shoring Equipment

-

Aerial Work Platforms, Scaffolding And Ladders

-

-

Industry Solutions

Agriculture Equipment Amusement Theme Parks Automotive Equipment Aviation Equipment Civil Commercial Construction Equipment Educational Facility Equipment Emergency Restoration and Response Entertainment Venue EquipmentEvent Rentals Film & TV Production Golf Course Management Equipment Government Services Healthcare Hospitality Equipment Industrial Manufacturing Equipment Marine EquipmentMining Equipment Oil Gas Equipment Real Estate and Property Maintenance Retail Maintenance Equipment Stadium Maintenance & Cleaning Equipment Utility Services

-

Industry Solutions

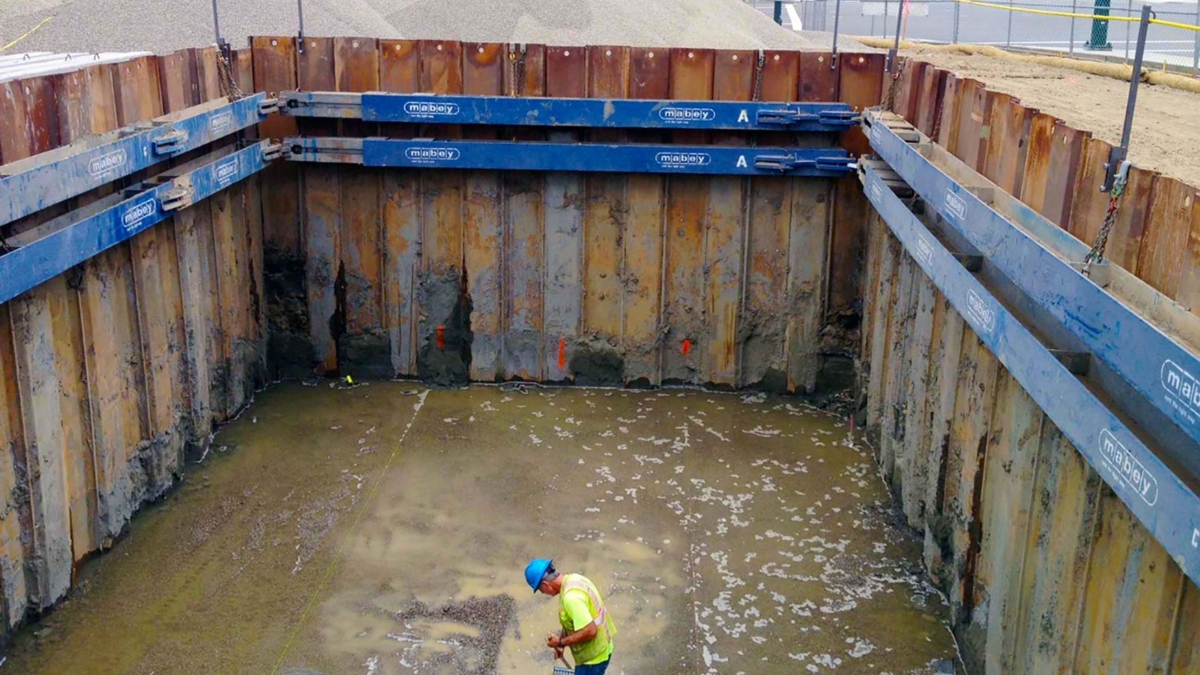

5 Tips to Stay on Top of OSHA Trench Safety Regulations

Construction companies are well-versed in the rigorous guidelines set by the Occupational Safety and Health Administration (OSHA). However, trench safety demands even greater attention and vigilance. Excavation sites are inherently dangerous, and the potential hazards, such as deadly cave-ins and collapses, are very real. It's critical to prioritize the latest OSHA trench safety regulations, not only to safeguard your workforce but also to remain compliant with industry standards.

Trench Safety Tips

By keeping these safety tips at the forefront, you can demonstrate your commitment to creating a secure and responsible workplace for your entire team. Click any of the links below to learn more:

Review OSHA Trench Safety Regulations

In 2018, OSHA prioritized trench safety by implementing a national emphasis program that included revising regulations and updating resources. When OSHA introduces or alters a regulation, it typically establishes a timeline for implementation and outlines enforcement procedures. Employers are often given several months or even years to adapt to the new rule. However, in cases where the change is significant, such as with Trench Safety, immediate and drastic action may be necessary.

When reviewing the OSHA trench regulations, you'll notice that they vary from trench to trench. For example, a trench more than five feet deep and not conducted on stable rock must have a protective system in place. If the trench is 20 feet or more, input from a registered professional engineer is necessary. It's crucial to stay up to date with the latest OSHA trench safety regulations to ensure a safe and compliant worksite. Regularly reviewing the regulations and understanding any recent updates or modifications is critical in ensuring you adhere to the latest safety protocols and procedures. Additionally, educating your team about these regulations is crucial to promoting awareness and preventing accidents or injuries on-site.

Atmospheric Hazards

Working in trenches can be dangerous due to the possibility of hazardous atmospheric conditions, which can cause harm to workers' health and safety. Gases such as methane and carbon dioxide can build up in trenches, leading to a lack of oxygen and the risk of asphyxiation. According to OSHA regulations, employers are required to test the atmosphere in trenches greater than four feet before allowing workers to enter. If hazardous conditions exist or may be expected to develop, employers must ensure that emergency rescue equipment is readily available. This equipment, including breathing apparatus, a safety harness and line, or a basket stretcher, must be attended to when used.

Potential Toxic Gases

Like atmospheric hazards, workers' health and safety are at great risk when toxic gases accumulate in trenches. These gases could come from decomposing materials or chemical leaks, and inhalation could lead to respiratory problems, poisoning, or death. OSHA mandates that employers thoroughly assess the potential sources of these gases to prevent exposure to workers. This assessment should include a comprehensive evaluation of all materials present in the workspace and their potential risks. Gas monitoring equipment should be strictly implemented to detect hazardous gases in the air. These monitors should be placed where workers are most likely to be exposed to toxic gases and regularly checked to ensure correct functionality. Additionally, ventilation systems should be installed to maintain a safe working environment and minimize hazardous gas accumulation. These include exhaust fans, blowers, or other ventilation systems that can quickly and efficiently remove toxic gases.

Debris, Loose Rock, or Water Accumulation

It may seem obvious that when trenches are dug, they often come across debris, loose rocks, and water. These hazards can create an environment susceptible to slips, collapses, and cave-ins. OSHA strongly recommends employing proper support, sloping, or shielding systems to prevent collapses. It's also essential to conduct regular inspections to identify and eliminate any debris, rocks, or water that may compromise the trench's stability. By doing so, you can establish a safe and secure working environment for all workers, reducing the likelihood of accidents and injuries.

Types of Excavation Protective Systems for Trench Safety

Per OSHA guidelines, employers must take measures to prevent workers from cave-ins by:

Sloping and benching the sides of the excavation: Trench walls are formed at an angle, creating a wider and safer pit. This method is more accessible and provides better safety.

Supporting the sides of the excavation: This approach is useful for narrow trenches where there isn't enough space for sloped walls. Hydraulic or air pressure can be used to generate force that prevents collapse.

Placing a shield between the side of the excavation and the work area: Shields, or trench boxes, are placed between the excavation's side and the work area. This protects workers against trench collapses.

Sometimes, the type of protective system required is well-known and easy to use. At other times, employers undertake the process of designing a custom-engineered protective system. While designing the protective system, soil classification, depth of cut, water content of soil, weather, climate, and other operations in the vicinity must be considered. Employers can choose the most practical design that provides the necessary protections. However, any system used must meet the required performance criteria.

Competence Is Confidence with Competent Person Training

As part of their obligation to ensure the safety of their workers, employers appoint a competent person to identify potential hazards and take corrective action to eliminate them. In line with OSHA guidelines, the competent person has the authority to promptly address unsanitary, hazardous, or dangerous working conditions.

Sunbelt Rentals offers in-person OSHA Trench and Excavation Competent Person Training if your project requires a certified representative. Our course provides a comprehensive understanding of the OSHA Subpart P Standard, covering everything from soil classification and protective system inspection to structural ramp design, water removal equipment monitoring, and site inspections. Students who complete the course successfully will receive a wallet-size certificate valid for three years, indicating that they are certified competent persons capable of ensuring worker safety and complying with OSHA regulations.

Call in the Experts at Sunbelt Rentals

Trench safety should never be taken lightly. When in doubt, it's critical to seek expert guidance and support to avoid any catastrophic consequences. The Trench Safety team at Sunbelt Rentals is focused on equipping work crews with effective solutions to keep trench projects compliant and workers safe.

With locations nationwide, we are committed to assisting you throughout your project, offering you state-of-the-art protective systems, site-specific engineered solutions, and industry-leading service.

Are you planning your next Trench and Excavation project?

Contact the Trench Safety rental experts at Sunbelt Rentals for all your Trench Safety training and equipment needs.

Trench Safety Resources

Dive deeper into Trench Safety with these related articles, blogs, and success stories.